TAVAPLAC

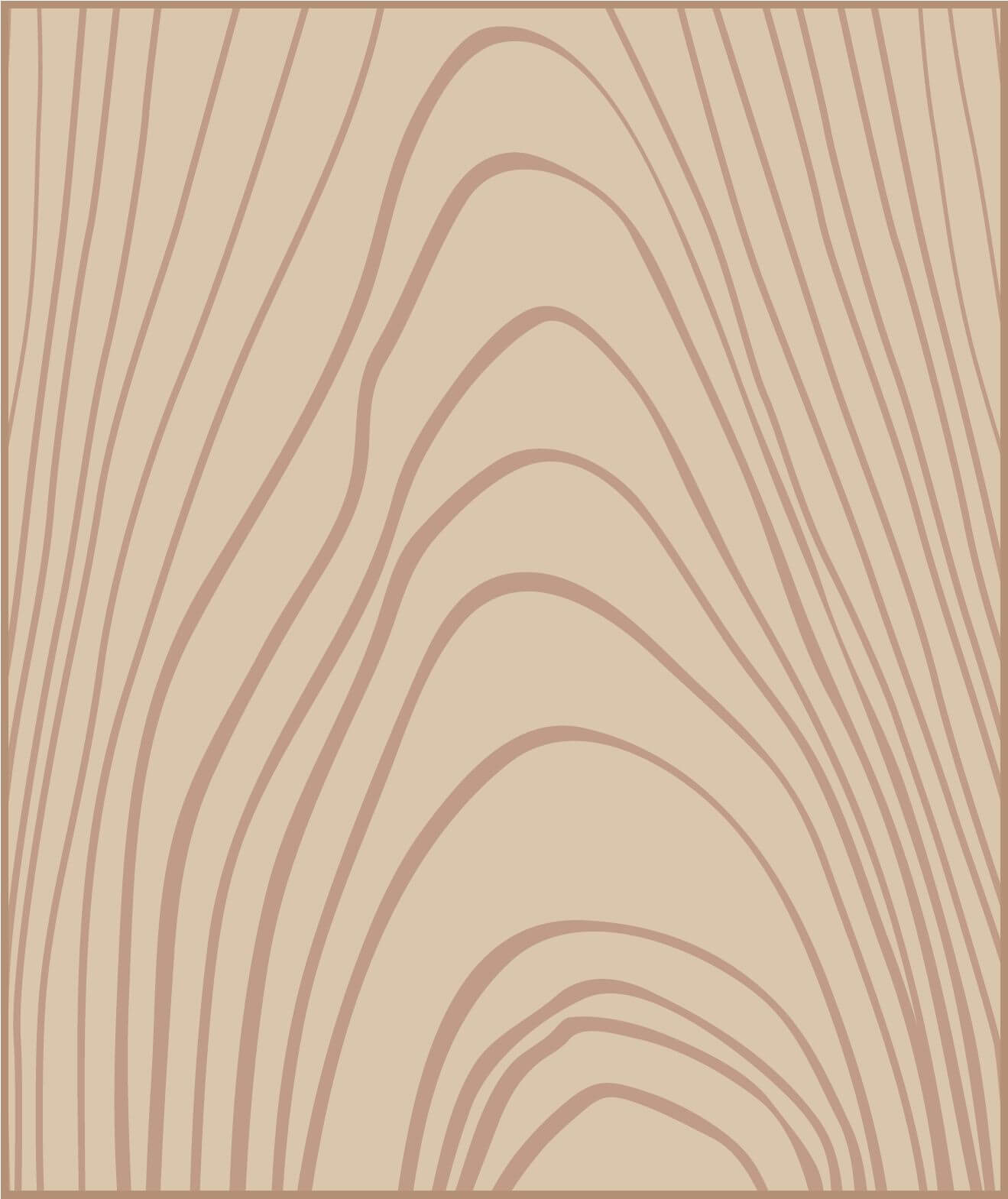

The application of veneer in the domain of interior building is not always easy. Apart from the choice of the type of wood there are requirements for uniformity, veneer design, panel width and assembly that need to be considered. TAVAPAN has many years of experience in the realisation of challenging projects in this domain. Therefore, veneered boards are not standard goods to us and we produce them on order.

Advantages

The use of veneer makes sense, economically as well as ecologically. Veneer is produced with a high degree of recovery and has a high coverage in its processing to veneered panels. This eventually prevents waste of precious wood species.- Order-related production

- Personal advice

- Reliable quality

- Veneer sample on demand

- Short delivery time of 1 - 3 weeks